Tensile structures

Enhance the skyline

The next generation of superior tension membrane structures are beautifying skylines worldwide. We have the teachnology to help yo do the same.

Shade for large areas. Sun protection and Ultra-violet protection. Design-friendly options for architects and strustural professionals. So many advantages.

islandbutterfly together with FERRARI Precontraint fabric technology offers world of sophisticated and practical solutions.

Explore the possibilities with us.

Creative expressions

The islandbutterfly New-age Architectural Membrane Structures are installed to detailed specifications. These design friendly structures are used as:

- Sun-shade roofs of open air restaurants, cafes, entrances of hotels and other commercial buildings.

- Uniquely designed roofs of car parks, swimming pools, bus and train stations, walkways at parks, residences, children’s play areas.

- Large scale sized roofs of open air entertainment centres, stadiums, sports complexes and exhibition centres.

The islandbutterfly New-age Architectural Membrane Structures are suitable as temporary or permanent modular structures for both residential and commercial buildings.

Flexibility and choice

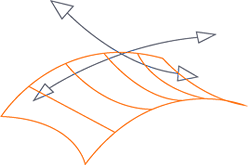

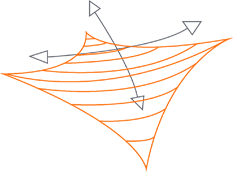

Tensile membrane structures are a perfect combination of architecture and engineering. These structures are light weight, flexible in forma, versatile in function and offer a range of dynamic, exciting three dimensional design options.

Tensile membrane structures come with many advantages of fabric architecture and offer possibilities of structural ingenuity in arrange of structural scales. They require minimal number of beautifully crafted components while giving unlimited freedom of imaginative design. The membrane fabrics used are flexible, durable and come in wide range of contemporary colours that add charcter to any environment.

Technical inspiration

A key component of a the islandbutterfly New-age Architectural Membrane Structure is the tensile fabric. The kind of material you select will depend on your structure-design, durability, and aesthetic appeal and location requirements for the application.

Commonly known as tensile fabric structures, these products are also referred to as tension membrane structures, architectural membrane structures, shell structures and fabric structures.

A tension fabric structures is a membrane (fabric) maintained under pre-stress (tension) state by structural elements and supporting systems.

Advantages of islandbutterfly new-age architectural membrane structure

- Can disperse natural light with condensed heat load (Excellent alternative to poly carbonate or glass as roof glazing system).

- Higher light transmission during daytime (Sufficient to reduce artificial lighting requirement by 5% - 20%).

- Absorbs solar energy (4% - 17%) and reduces the heat load.

- Low maintenance as compared to glass.

- Minimal site interruptions since the membranes structures are manufactured in the factories.

- No extension joints since the membranes structures are welded into a single weatherproof skin.

- Designed for rapid construction.

- Larger span for more coverage.

islandbutterfly new-age architectural membrane structure are available in many free tension fabric forms and shapes

| Cones: Singel cone, multiples cones, fixed edges, centenary edges, cables edges, height variations, inverted cones etc. | Arched vault: Parallel arches and crossed arches | Hyper: Two opposing high points and two opposing low points |

|

|

|

Polyvinyl chloride (PVC)

On the basis of mechanisal properties, weight and strength the international convection has differentiated four distinct grade of fabrics. After the shape analysis a project engineer decides the grade of fabric to used.

PVC has been widely used for fabric structure over twenty years.The fabric is translucent and the addition of white pigments increases its resistance to UV rays. Fleexibility can be improved by adding plasticized (these might eventually drift to the surface attracting dirt and turning the PVC brittle, discolored and hard) PVC is welded using high frequency welders.

The coating on the PVC is of utmost importance. A smooth and shiny coating facilitates to keep the fabric clean, it therefore essential to select the most appropriate fabric type during fabricaion and installation.

Hotline 077 207 8446